Dry Wall Screws

| Material: | Stainless Steel |

|---|---|

| Type: | Pan Head |

| Groove: | Cross |

| Connection: | Self Tapping |

| Head Style: | Pan |

| Standard: | DIN, GB, ANSI, BSW, JIS, GOST |

Product categories

Get a quote

Related Products

Related products

Dry Wall Screws

| Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) |

| 3.5*13 | #6*1/2 | 3.5*65 | #6*2-1/2 | 4.2*13 | #8*1/2 | 4.2*102 | #8*4 |

| 3.5*16 | #6*5/8 | 3.5*75 | #6*3 | 4.2*16 | #8*5/8 | 4.8*51 | #10*2 |

| 3.5*19 | #6*3/4 | 3.9*20 | #7*3/4 | 4.2*19 | #8*3/4 | 4.8*65 | #10*2-1/2 |

| 3.5*25 | #6*1 | 3.9*25 | #7*1 | 4.2*25 | #8*1 | 4.8*70 | #10*2-3/4 |

| 3.5*29 | #6*1-1/8 | 3.9*30 | #7*1-1/8 | 4.2*32 | #8*1-1/4 | 4.8*75 | #10*3 |

| 3.5*32 | #6*1-1/4 | 3.9*32 | #7*1-1/4 | 4.2*34 | #8*1-1/2 | 4.8*90 | #10*3-1/2 |

| 3.5*35 | #6*1-3/8 | 3.9*35 | #7*1-1/2 | 4.2*38 | #8*1-5/8 | 4.8*100 | #10*4 |

| 3.5*38 | #6*1-1/2 | 3.9*38 | #7*1-5/8 | 4.2*40 | #8*1-3/4 | 4.8*115 | #10*4-1/2 |

| 3.5*41 | #6*1-5/8 | 3.9*40 | #7*1-3/4 | 4.2*51 | #8*2 | 4.8*120 | #10*4-3/4 |

| 3.5*45 | #6*1-3/4 | 3.9*45 | #7*1-7/8 | 4.2*65 | #8*2-1/2 | 4.8*125 | #10*5 |

| 3.5*51 | #6*2 | 3.9*51 | #7*2 | 4.2*70 | #8*2-3/4 | 4.8*127 | #10*5-1/8 |

| 3.5*55 | #6*2-1/8 | 3.9*55 | #7*2-1/8 | 4.2*75 | #8*3 | 4.8*150 | #10*6 |

| 3.5*57 | #6*2-1/4 | 3.9*65 | #7*2-1/2 | 4.2*90 | #8*3-1/2 | 4.8*152 | #10*6-1/8 |

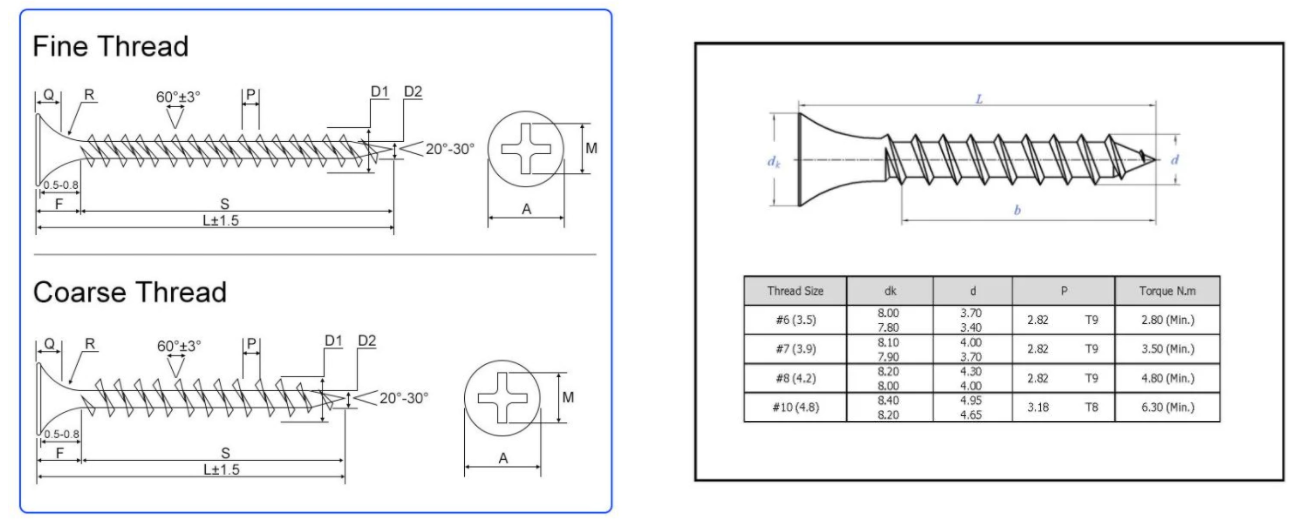

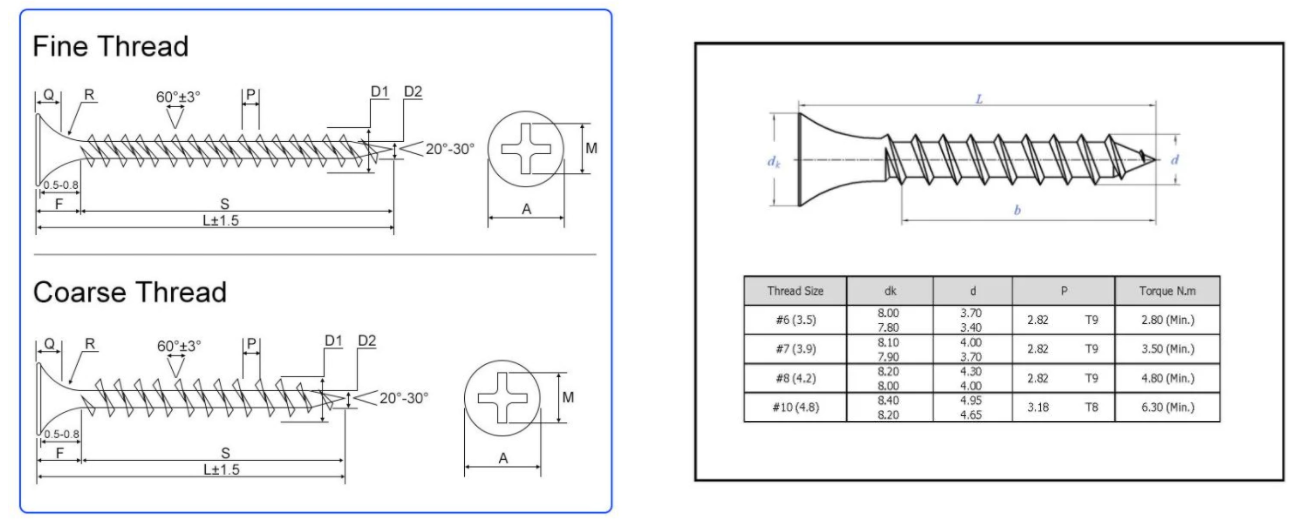

Drywall screws (sheetrock screws) are specialized self-tapping screws that usually feature a bugle head that is designed to attach drywall to studs, and a phosphate finish. In the construction industry, sheetrock screws have many alternative uses because they are relatively inexpensive, feature a flat head that is less prone to getting pulled through the wood, and thin, making these self tapping drywall screws less likely to split the wood. They are available with a coarse thread, fine thread, high-low pattern thread, and sometimes feature a trim head rather than a bugle head.

1. Strength and durability: Drywall screws are usually made to be very strong and not easy to break, which means they are able to firmly attach the drywall to the wall and remain stable even when bearing weight or moving.

2. Corrosion resistance: Many drywall screws are specially coated or made of stainless steel to prevent corrosion, thereby extending their service life and maintaining fixed function.

3. Designed to prevent damage to the plate: Drywall screws are usually designed to minimize damage to the plate. Their tips are able to penetrate drywall quickly without causing unnecessary cracks or breaks.

4. Easy to use: drywall screws are relatively simple to install and require no special tools or skills. Installation can usually be done using only a screwdriver or electric drill.

5. Various sizes: Drywall screws come in various lengths and sizes, which can be used for different thicknesses of drywall and different types of support frames.

6. Good fastening effect: The thread design of these screws is conducive to anchoring firmly in the material, providing strong support and preventing the drywall from loosening over time.

7. Detachable: If the drywall screws need to be replaced or repaired, the drywall screws can be screwed out relatively easily, making the repair work easier.

8. Economical efficiency: drywall screws are generally more economical than other fastening materials, while providing reliable performance.

Scope of application:

Cross Recessed Pan Head Tapping Screws are widely used in many fields because of their convenient installation and strong adaptability. They are commonly used for:

1. Tighten sheet metal or components

2. Connection of wood or density board in furniture manufacturing

3. Fast fixing of plastic parts

4. Assembly of electronic products

5. Maintenance and installation of mechanical equipment

6. Detail fastening in building decoration

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:Do you accept the use of our logo?

A. If you have a large quantity, we absolutely accept OEM.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,For the first time customers, we can accept L/C

Related products

Related products

Looking for the best fasteners?

Schedule a Consultation

Contact us now for a detailed quote on this product.